Capabilities

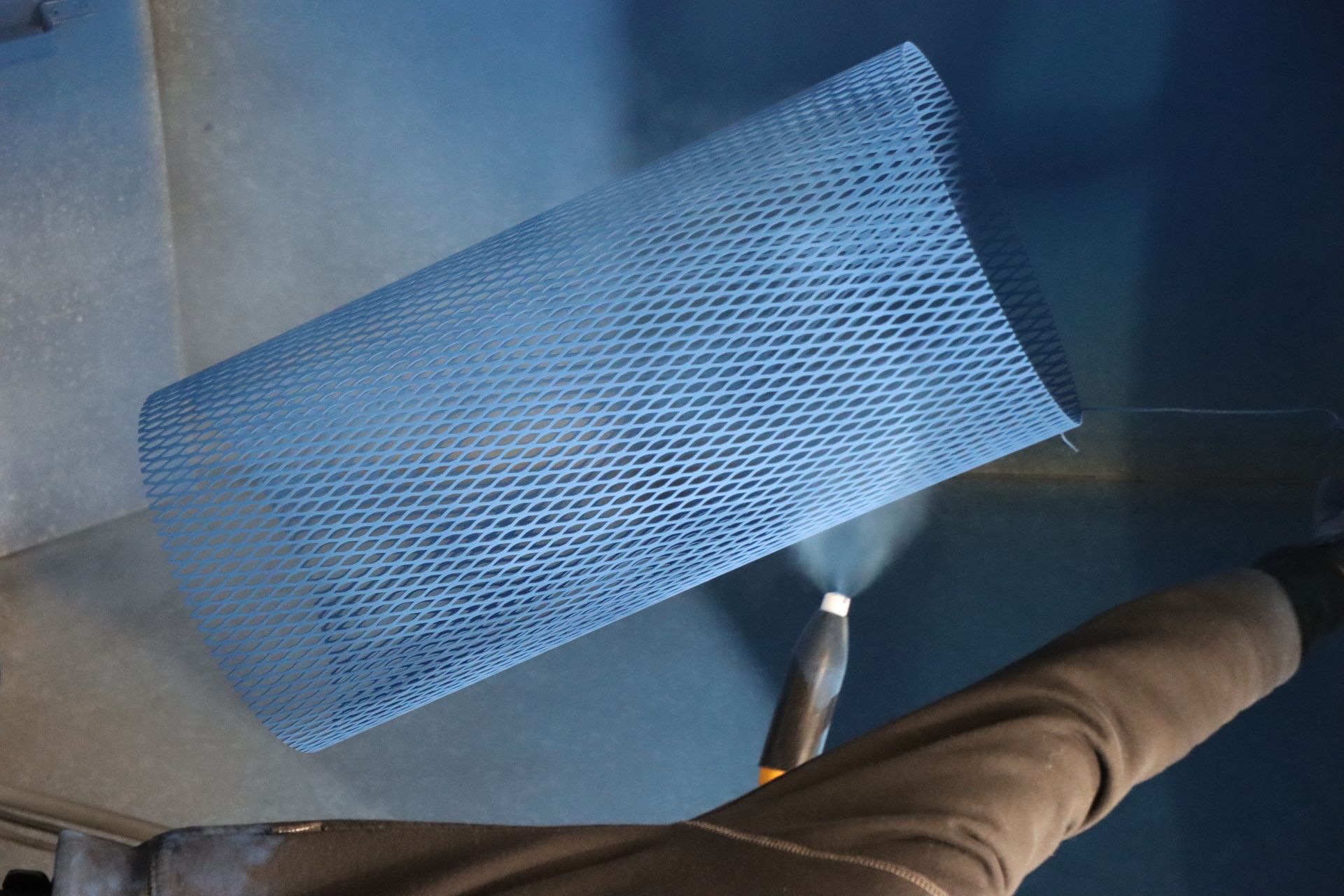

A qualitatively high-value filter is engineering at its best. Because it is far more than just a piece of media in a frame. A large amount of engineering and development time is integrated into a high-tech product. The most varied processes are used to bring the filter media into the required filter shape. Some of these are pleating, welding, impregnation of materials and bonding, then sealing with compounds. The frame and filter medium are joined with the final product specific filter assembly.

This tireless commitment and expertise have paid off over the years because we are pleased that many of our exceptional products are based on our development work.

In the future, we will continue to develop intelligent and effective products which are leaders in their sector.

Slide title

Write your caption hereButtonSlide title

Write your caption hereButton

- 3 Axis HASS TM1 Tool room CNC mill

- Laser cutter

- Media pleater

- Edge banding

- 5x 2 part polyurethane resin dispensing machine

- XY robotic polyurethane dispenser

- Band saw

- Guillotine (electrical & manual)

- 2 Swing beam clicker presses

- Graco 6 bar high pressure air less spray additive impregnation

- Punch

- 5 person spray gluing booth

- Oiler (sheet & hand)

- Nibbler

- Break press

- Mig welder

- Tig welder

- Spot welder

- Fly presses

- Swager

- 3D cloud based CAD

- CAD cam (Onshape & OneCNC)

- Roller (sheet metal)

- Topas ALF 114 filter tester

- Industrial oven

- Powder coater

- Automated hotmelt lamination line

- Automated hotmelt gluing machine

- 3D rapid prototype printer

- Filter branding station

- SPM 91 SPL Blade pleating machine

- SPM 92 XTS Slitter

- SPM 95 XCUT

- 3 Axis HASS TM1 Tool room CNC mill

- Laser cutter

- Media pleater

- Edge banding

- 5x 2 part polyurethane resin dispensing machine

- XY robotic polyurethane dispenser

- Band saw

- Guillotine (electrical & manual)

- 2 Swing beam clicker presses

- Graco 6 bar high pressure air less spray additive impregnation

- Punch

- 5 person spray gluing booth

- Oiler (sheet & hand)

- Nibbler

- Break press

- Mig welder

- Tig welder

- Spot welder

- Fly presses

- Swager

- 3D cloud based CAD

- CAD cam (Onshape & OneCNC)

- Roller (sheet metal)

- Topas ALF 114 filter tester

- Industrial oven

- Powder coater

- Automated hotmelt lamination line

- Automated hotmelt gluing machine

- 3D rapid prototype printer

- Filter branding station

- SPM 91 SPL Blade pleating machine

- SPM 92 XTS Slitter

- SPM 95 XCUT

Want to collaborate on a project?

Need to use our facilities?

Talk to our Technical team!

Contact Us Today!

Thank you for contacting us.

We will get back to you as soon as possible.

Uh oh, there was an error sending your message.

Please try again!

9 Sketty Close, Brackmills Industrial Estate, Northampton, NN4 7PL

Telephone:

Email:

Telephone:

+44 01604 707750

Email:

Registered in England & Wales No. 02524269

VAT No. 430650134

All Rights Reserved | Filtration Control Ltd