As a leading filter manufacturer, FCL has unrivalled in-house research and development capabilities. Using industry-leading equipment, we can rapidly design, develop, test and certify air filter products for various applications. Testing is available to ensure our products meet or exceed the original filter manufacturer and demanding ISO standards.

We believe in harnessing the power of cutting-edge technology and unparalleled teamwork to push the boundaries of what’s possible.

Together, we're not just aiming to lead the market - we're defining it.

What We Test For:

Computer Aided Design (CAD)

CAD software has revolutionised how we visualise and create products, allowing us to explore new designs in various materials. CAD enables our engineers to push the boundaries of innovation, delivering high-quality, high-performance filters that redefine industry standards and reach the market faster.

More About What We Offer:

FCL HVAC Filters

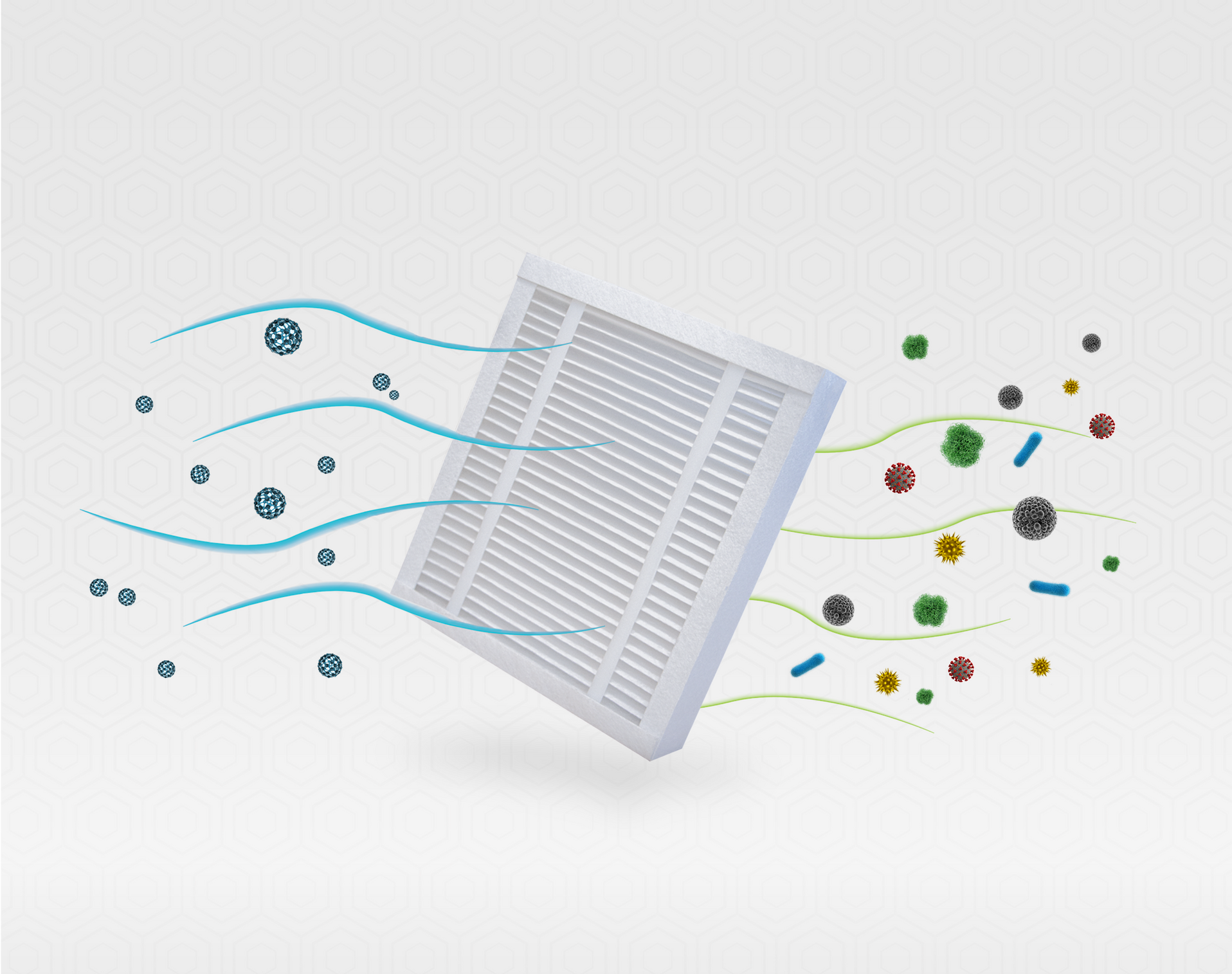

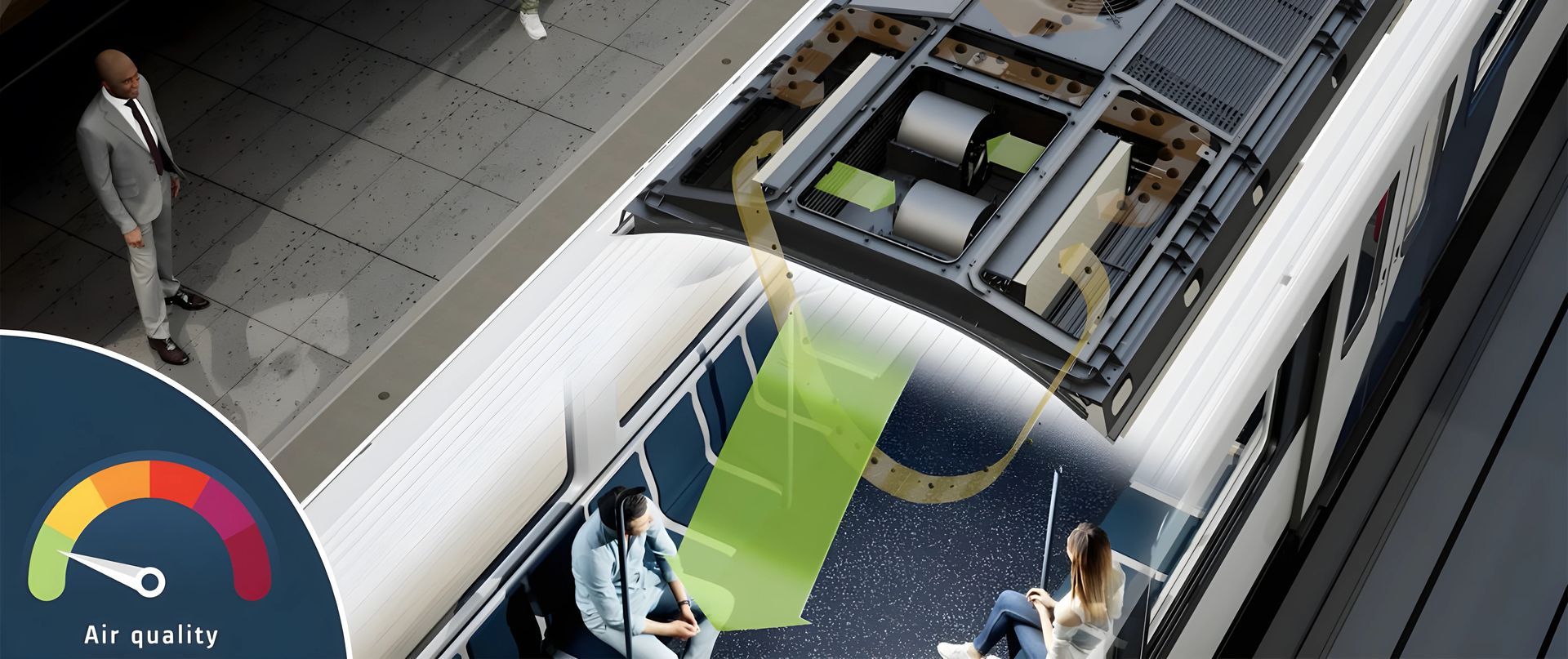

Our ISO certified HVAC filters are designed, manufactured, and rigorously tested in-house, engineered to capture airborne particles down to a fraction of a micron.

PEPA-F™

Our PEPA-F™ filters for HVAC systems improve air quality and ensure fine filtration with minimal integration impact on HVAC systems.